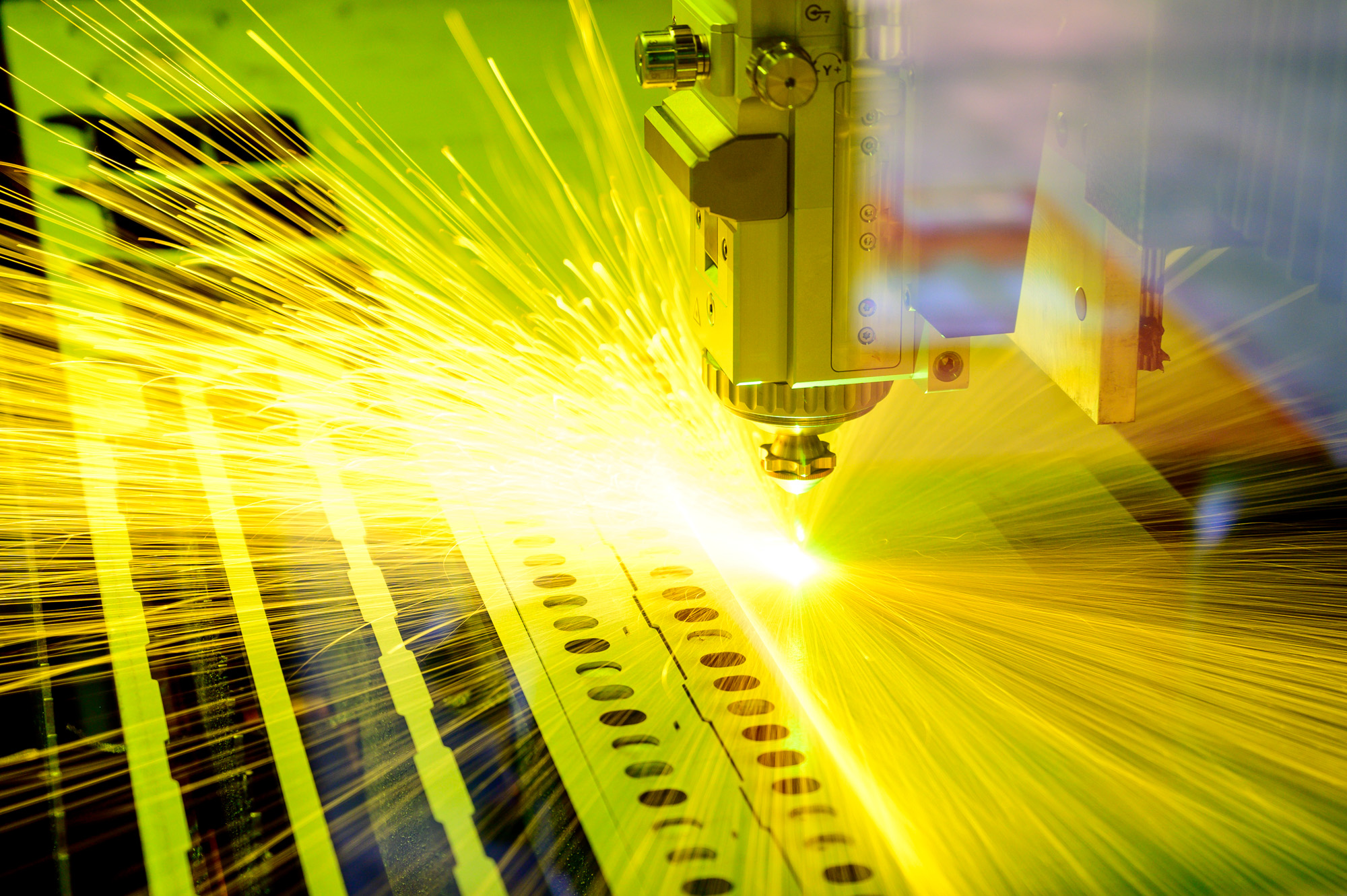

Kilner’s Engineering can laser cut a variety of materials accurately and efficiently at our Brisbane factory.

Laser cutting has many advantages over Plasma, Oxy, Guillotining, Cropping and Punching. It is fast to setup from one material to the next and no special tooling is required. Compared to Oxy and Plasma cutting it only has a small heat affected zone and no mechanical stresses are applied to the material unlike Punching and Guillotining. Laser cut parts have a high accuracy, a good cut quality and finished parts come straight from the machine.

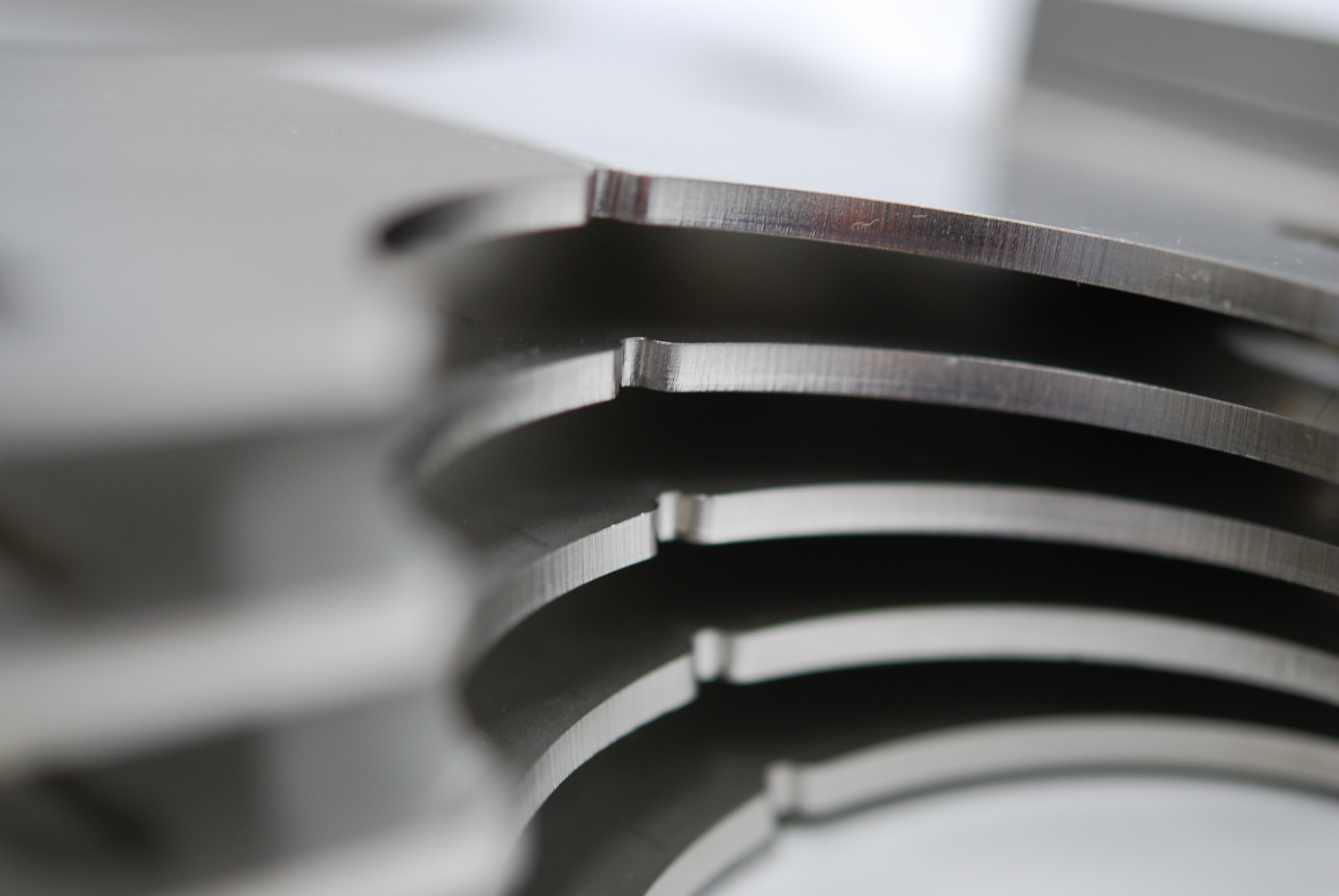

Finished parts are produced straight from the laser with clean dross free edges on most materials, therefore grinding or finishing is generally not required. Parts can be accurately and efficiently prototyped before going to full production. Once a component has been laser cut it can then be folded, formed or machined as required.