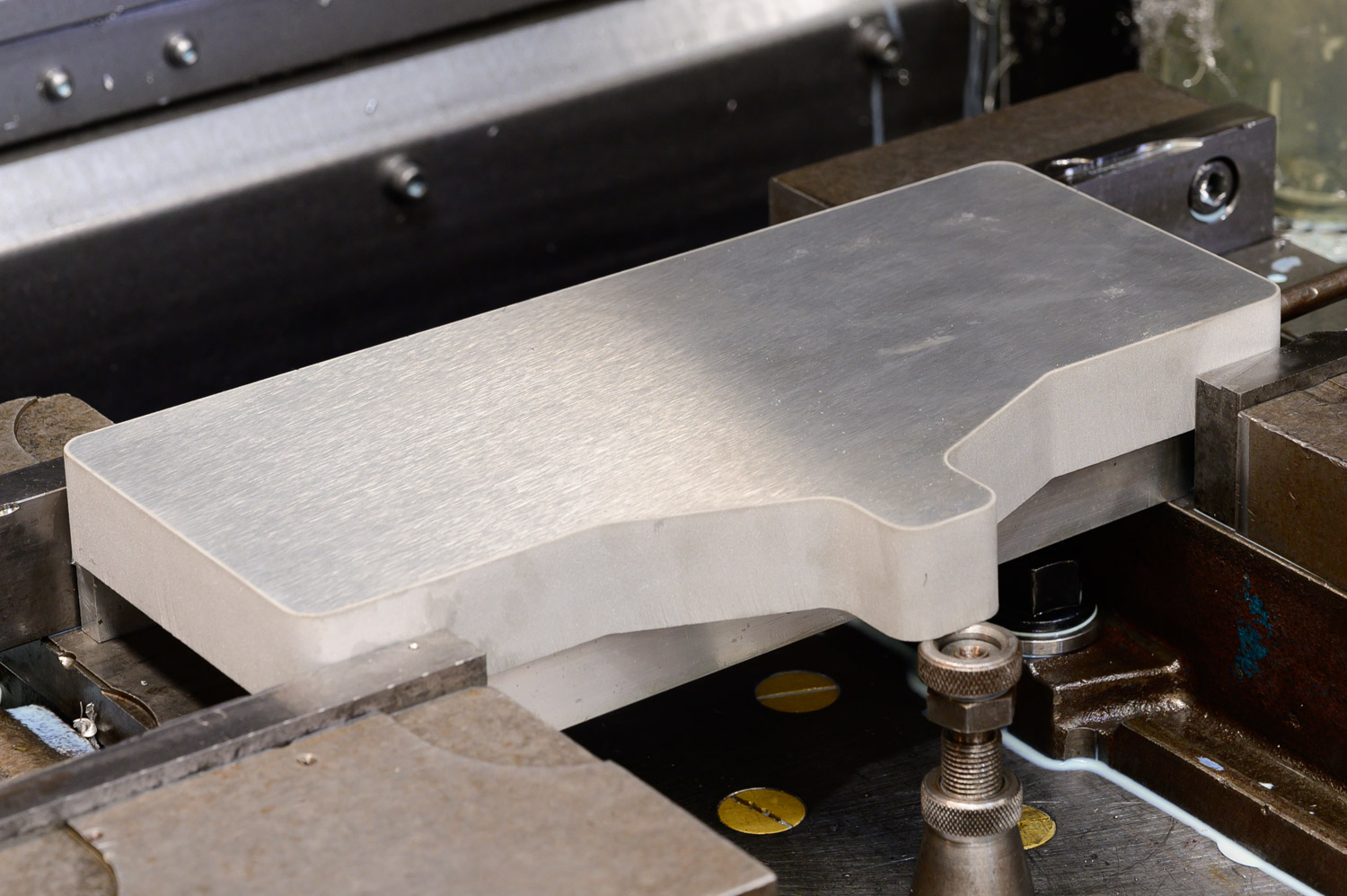

Kilner’s Engineering has a flexible range of cnc machining options available at our Brisbane facility. Investment in high quality Japanese Machine Tools means we can offer a reliable and efficient machining service. Our equipment is programmed and operated by highly experienced tradesmen, this means we can deliver high quality parts with efficiency.

We have a broad scope of CNC machining capabilities in our 1810m2 Brisbane facility including our new Mazak Variaxis C-600 simultaneous 5-axis vertical machining center, which complements our heavy duty 4 Axis and 3 Axis machines. With production work we can divide the work area into separate zones for fixtures to be loaded/unloaded while the machine is working in the other zone. Our vertical machining centers have high rapid travel speeds and fast tool change times to maximise productive capacity.

Kilner’s Engineering delivers a sophisticated and diverse manufacturing service, offering a complete turnkey service from initial design to final assembly or any stage in between.